Are you searching for a tile cutter machine? Then you are at the right place to find the best cutter that will leave you with long memories. A manual tile cutter is a simple scoring tool used to cut straight lines in porcelain and ceramic tiles. Purchasing a tile cutter machine is a crucial step for making your work look elegant.

They are expensive and the only precise way of receiving clean cuts during the operation. Additionally, the models utilize a two-step process of scoring then snapping the tile. Mostly, tile cutter machine design works on both ceramic and porcelain. Furthermore, the dual-plated chrome-plated rugged steel rails and ball-bearing construction ensure smooth scoring on large tiles.

The machine is useful for cutting ceramic tiles to specific sizes and shapes. Additionally, it helps in removing irregular tile corners to facilitate proper tile fitting. For beginners, you don’t need to worry anymore since the article comes with the full process of using a manual tile cutter. The following is our research on how to use a manual tile cutter machine and consider factors before purchasing one.

Table of Contents

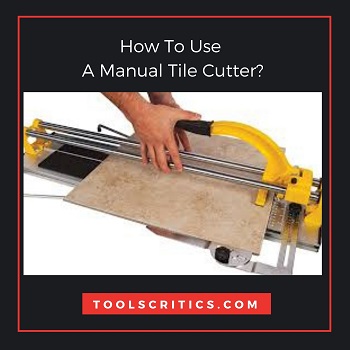

Step By Step Guideline of How to Use a Manual Tile Cutter?

If you decide to cut your tiles manually, a manual tile cutter is a perfect choice. It is safer, more comfortable, and a cheap method. Additionally, it is the ideal tile cutter in making straight cuts on ceramic tiles. However, you can’t use it for making mixed cuts or on stones. The first score is quite important when using a tile cutter.

A continuous and reliable motion will help you score the tile quickly. Make sure that you apply less pressure to avoid tile breakage and internal cracks while snapping. Below are eight steps of using a manual tile cutter.

Step 1: Purchasing of the tile cutter

For performing diagonal cuts, purchase a tile cutter with more width than corner to corner distance. Through the help of a rotating guide, you will be able to make cuts at different angles.

Step 2: Practicing the cut

If you are a beginner, you need a practice cut using scrap or inexpensive pieces of tiles. Regular practicing enables you to make the perfect outcome of the project.

Step 3: Marking for the cut

The pencil is best in highlighting the cuts on the tiles on both sides. It is important to make marks on the material to help in making smooth cuts.

Step 4: Sliding the level

Sliding the machine level is another step that helps in performing the task smoothly. With the tile cutter, you will need to push the blades’ level to come close to you.

Step 5: Placing the tiles

While keeping the glazed side up, you should place your tile into the tile cutter. Ensure that the markings are respectively over the guideline. For cutting many tiles similarly, you need to adjust the protractor gauge. Ensure that the tile is against the line and properly fixed.

Step 6: Moving the level

Moving your level, you need to adjust the lever such that the tungsten is over the marked line. Additionally, to make the marking edge weak for cutting quickly, you need to push the bar down towards the tile edge by using equal pressure continually.

Step 7: Cutting it into two

Use pressure on the weakest line on either side of the shoreline by pushing down the lever.

Step 8: Make both sides smooth

Use sandpaper or a sharpening stone for smoothening the sides of the cut edges. During the molding process, when the cut edge stays hidden, there is no need to smoothen it.

Advantages of using manual tile cutter machines

- The model is handy in allowing free movement to varied places

- It produces less amount of dust, ensuring convenient working in the living room.

- They are incredibly reliable and noticeably cleaner.

- Manual tile cutters ensure easy adjustment in your work since no restrictions to heavy-duty equipment or plugging.

- The tile cutter performs intensive cuts using minimal effort.

- The model’s Lightweight enables a long time working without fatigue.

- Manual tile cutters work without the need for electricity, making it a cheap model.

FACTORS TO CONSIDER BEFORE PURCHASING A MANUAL TILE CUTTER

Are you planning to buy a manual tile cutter? OK, then you are at the right place, Manual tile cutter will give your job a good-looking and smooth finish. However, there are different factors to consider before purchasing the tile cutter.

1. Dimensions

The length is a crucial determinant of the cutting capacity. This often ranges from 30cm to above 120cm. The Cutting width should be smaller to stabilize the machine and improve the cutting process. Furthermore, the diagonal should be higher than the length; therefore, take note of your relevant tile dimension if you’re deciding to lay at 45 degrees.

3. Accessories

Different models will come with accessories like a graduated guide and side stops facilitating high volume work or adjustment.

3. Rails

Rail is an essential factor that you can’t ignore before purchasing a tile cutter. They facilitate the moving of the wheel. Consider two tracks that produce better cut precision and robustness.

4. Scroll wheel

The wheel, in titanium carbide or tungsten, has a diameter that ranges from 6 to 22mm that show maximum tile thickness. It will be challenging to work with a 15mm tile with a cutting wheel off only 6mm wide. Some models will let you quickly change the motor’s diameter, depending on the tile you’re working with.

5. Separator

The separator may either be mobile or fixed. Note that a fixed separator will save time since there is no need for repositioning after the wheel pass. Note that cutting force may exceed one tone. However, 500kg is enough for solid stone and ceramic cutting.

Final Words

Purchasing the best tile cutting machine is a crucial step for ensuring effective and efficient working. There is a wide range of factors and features that customers need to consider before making the best choice. Tile cutting machines come with high quality ensuring long-term service.

Therefore, our esteemed customers need to visit our website and study the efficiency of a manual tile cutter machine safely before purchasing one to avoid incurring maintenance costs. Besides, the machine is important for beginners since it is low in price, easy loading, and simple usability. Please do not be left out! Buy your device today and enjoy the benefits.

1 thought on “How To Use A Manual Tile Cutter [Quick Step By Step Process]”